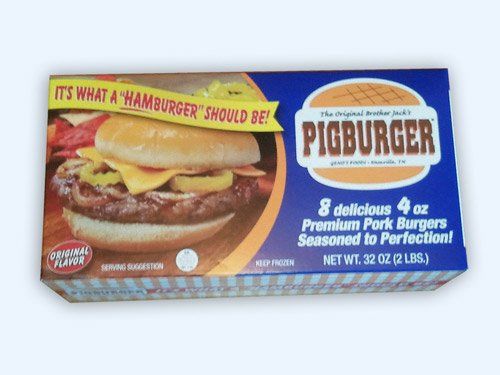

A customer in the retail food industry contracted Accurate Paper Box to manufacture this custom die cut carton for one of their food product lines. Designed as a meat product package, manufacturing required several complex processes. Working from the supplied engineering drawings, we designed the dies which included cutting and scoring rules.

Die cutting and scoring were performed on our precision Bobst die cutter. After the carton was die cut and scored, it was then glued using industrial glue specially formulated for food grade packaging. This was completed on our International straight line gluer.

In addition to the die cutting and gluing, we were also responsible for all of the printing. The carton is composed of a solid bleach sulphate paperboard, printed on our state of the art Planeta 6-color offset press. Printing utilized process colors, with an aqueous coating.

The boxes were produced maintaining tolerances of ±1/16”. Overall, finished dimensions of the product were 8.9375” long x 4.6250” wide x 3.000” high. 10,000 units were produced for this order, which were delivered in 4 weeks to the customer’s location in Powell, Tennessee. Accurate Paper Box specializes in manufacturing custom packaging with fast turnaround times. For further details about this project please see the chart below or contact us directly.